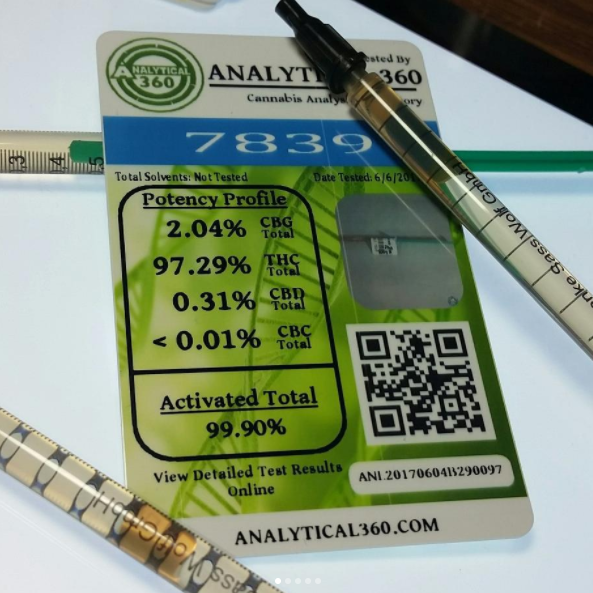

The Gold Standard

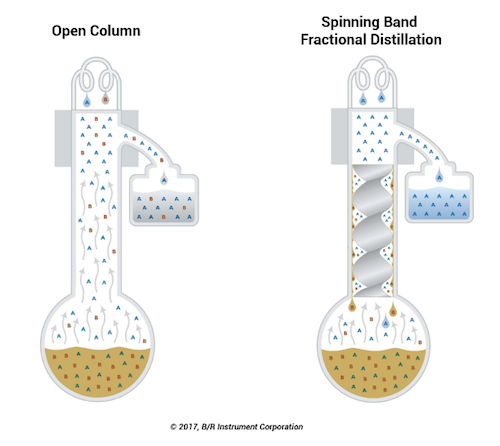

Achieve higher purities than possible on a wiped film or short path set up, with a fraction of the effort. Technology suited perfectly to the job paired with automated controls allows you to create liquid gold. All distillations attempt to separate a lower boiling point material (A) from a higher boiling point material (B). Spinning band distillation creates intimate contact between the vapors and the condensate in a dynamic process by using a helix rotating at high speeds inside the distillation column. The rotating “band” forces vapors into contact with a very thin layer of condensate that is refreshed thousands of times per minute. This creates the maximum amount of vapor-liquid contact. More interaction between the vapor and liquid phases equals a higher purity.

Advantages Over Wiped Film

Wiped Film has several hinderances in its production of cannabis distillate. -Constant tinkering with the feed valve requires an attentive operator. -Any residual solvents or other volatile compounds can instantaneously vaporize and cause spattering. Spattering leads to contamination and weaker vacuum levels. -Wiped film has low separating power and therefore requires more pre and post processing to reach purity comparable to spinning band.

Advantages Over Short Path

Short Path system have become fairly popular as entry level distillation system for cannabis oil. However, many are cheaply made and poorly designed. -These systems often lack theoretical plates for quality separation. -No proper cold trap system (causes damage to vacuum) -The small length and diameter of these columns can easily cause flooding -Must break vacuum on the whole system to change receivers. This introduces oxygen and increases the overall time of the distillation.